Exploring the Impact and Success of Chinese Plastic Manufacturers

Introduction to the World of Chinese Plastic Manufacturing

The Chinese plastic manufacturers industry has established itself as a powerhouse on the global stage. They play a crucial role not only in supplying a wide variety of plastic products but also in shaping international trade dynamics. This article delves deep into the processes, innovations, and business strategies that define Chinese plastic manufacturers, highlighting their contributions to the global economy.

The Rise of Chinese Plastic Manufacturers

Over the past few decades, China has transformed into the world's largest producer of plastics. Factors contributing to this rise include:

- Cost-Effective Production: Chinese plastic manufacturers benefit from lower labor costs and a well-established supply chain, allowing for competitive pricing.

- Advanced Technology: Investment in modern technology has enhanced production efficiency, quality control, and product innovation.

- Export-Focused Approach: The Chinese government's policies have often supported export-driven growth, facilitating access to international markets.

Understanding the Manufacturing Processes

The manufacturing processes employed by Chinese plastic manufacturers are diverse and sophisticated:

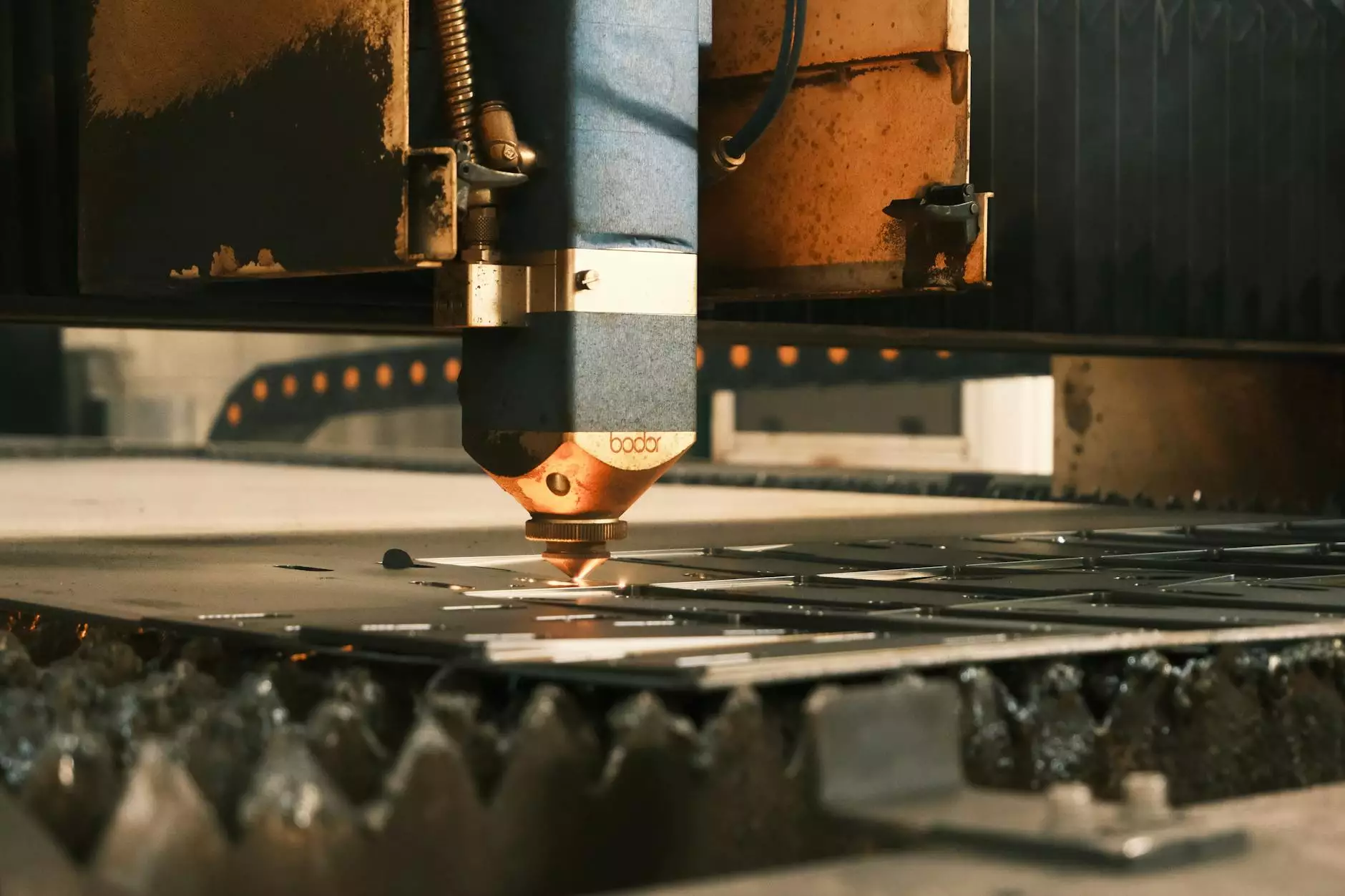

1. Injection Molding

Injection molding is a primary method used to produce complex shapes by injecting molten plastics into molds. This technique is highly efficient and capable of producing large quantities with consistent quality.

2. Blow Molding

Blow molding is commonly used for creating hollow plastic parts, such as bottles. This process uses air to form the plastic into the desired shape, allowing for the production of lightweight and durable containers.

3. Extrusion

The extrusion process involves forcing heated plastic through a die to create long continuous shapes. This method is essential for producing products like pipes, sheets, and profiles.

4. Thermoforming

Thermoforming utilizes heat to soften plastic sheets, which are then shaped into specific forms. This technique is often employed for items like trays, packaging, and shallow containers.

Innovations in the Chinese Plastic Manufacturing Sector

Innovation is a critical component of success for Chinese plastic manufacturers. They are continuously adapting and implementing new technologies to enhance productivity and environmental sustainability. Some notable innovations include:

- Biodegradable Plastics: With growing concerns over environmental impact, many manufacturers are exploring biodegradable options to reduce plastic waste.

- Recycling Initiatives: Advanced recycling technologies allow manufacturers to reuse plastic materials, contributing to a circular economy.

- Smart Manufacturing: Integrating IoT and AI into manufacturing processes enhances efficiency and enables real-time tracking of production metrics.

The Global Impact of Chinese Plastic Manufacturers

The influence of Chinese plastic manufacturers extends far beyond national borders:

1. Supplying Global Markets

China supplies a significant portion of the world's plastic products, ranging from consumer goods to industrial components. This supply chain dominance shapes pricing and availability across various sectors.

2. Strengthening International Trade

Through robust export strategies, Chinese plastic manufacturers have strengthened international trade relationships, fostering economic growth in many countries that depend on these products.

3. Setting Industry Standards

With their scale and focus on innovation, Chinese manufacturers often set trends and standards in the plastic industry, influencing practices worldwide.

The Role of Sustainability in Chinese Plastic Manufacturing

As environmental awareness grows, sustainability has become a pivotal focus for the industry. Chinese plastic manufacturers are adapting by:

- Reducing Carbon Footprint: Many companies are investing in cleaner production technologies and energy-efficient machinery.

- Implementing Eco-Friendly Practices: Emphasizing the use of recyclable materials and minimizing waste during production processes.

- Complying with Global Standards: Adhering to international regulations on plastic production and waste management to cater to global markets.

Challenges Faced by Chinese Plastic Manufacturers

While the outlook for Chinese plastic manufacturers is promising, they face several challenges that require strategic responses:

1. Rising Labor Costs

As China's economy grows, labor costs are increasing, prompting manufacturers to find ways to maintain competitiveness through automation and efficiency.

2. Environmental Regulations

Stricter environmental regulations, both locally and globally, are pushing manufacturers to rethink their practices. Compliance can mean higher costs and the need for investment in cleaner technologies.

3. Global Competition

Opportunity comes with heightened competition from emerging markets, necessitating constant innovation and adaptation to maintain market leadership.

Conclusion: The Future of Chinese Plastic Manufacturers

In conclusion, Chinese plastic manufacturers are at the forefront of a dynamic industry that plays a crucial role in the global economy. With their commitment to innovation, sustainability, and overcoming challenges, they are set to continue leading the market for years to come. Businesses and consumers alike can expect an ongoing evolution in plastic manufacturing that prioritizes not only functionality and efficiency but also environmental stewardship.

Call to Action

For those looking to engage with the pioneering world of Chinese plastic manufacturers or seeking high-quality plastic solutions, consider reaching out to experienced suppliers and manufacturers. Explore the vast options today and be a part of the ongoing transformation in the plastics industry.

For more information about our services, visit deepmould.net.